1、Explosion-proof motors shall not be dismantled at will; During maintenance, the explosion-proof surface of the components can not be used as the fulcrum of the crowbar, and it is not allowed to hit or impact the explosion-proof surface.

2、When disassembling the motor, firstly remove the hood and fan, use the casing wrench to remove the bolts of the end cover and the bearing cover. Then, using the round or copper rod to impact the shaft extension in the axial direction to separate the end cover from the base. Finally, Remove the rotor and the components, the explosion-proof surface should be placed upside down, covered with rubber or cloth pad, fastening bolts, do not lose the spring pads, etc.

3、When dipping and assembling, the insulating paint or dirt which attached to the explosion-proof surface should be cleaned, and it is not allowed to be scratched with hard objects such as iron sheets, but the uneven surface can be polished with oil stone.

4、If the explosion-proof surface is damaged, it is necessary to use lead-tin solder HISnPb58-2, flux 30% hydrochloric acid (for steel parts) or tin-zinc solder containing 58~60% tin. The flux is ammonium chloride 30%, zinc chloride 70%, add water 100~150% mixed solution (for cast iron parts), the combination of solder and parts should be firm, and the convex part should be smoothed to achieve the specified finish.

5、To prevent rust on the explosion-proof surface, shall apply oil or 204-1 replacement rust preventive oil to the explosion-proof surface.

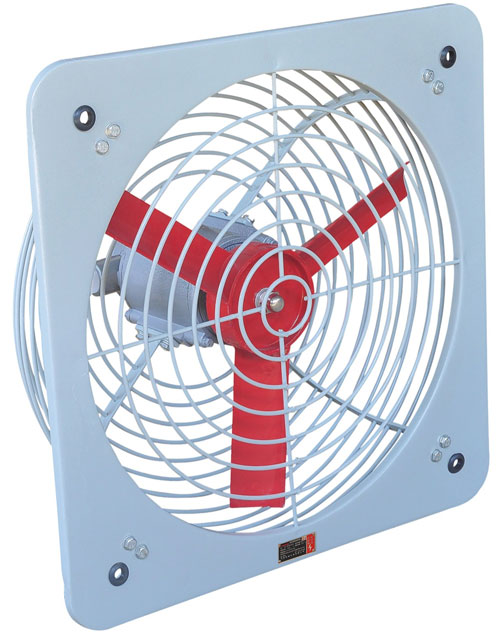

We mainly produce Explosion Proof Axial Fan, Explosion Proof Maintenance Free Led Floodlight and other products. We are experts in explosion-proof equipment. If you have any questions, please contact us.